WHAT WE DO!

KUORI transforms tomorrow’s materials today—bridging innovation and sustainability without compromise. Our biodegradable BIOWA grades upcycle olive pits and nutshells into high-performance products, reducing microplastic pollution. With Material B, we are developing a 100% bio-based material that naturally returns to the earth, while our patent-pending vulcanized rubber, Material C, will regenerate through chemical recycling. No landfills, no legacy just smarter materials engineered to protect the planet while outperforming the status quo. Explore how KUORI redefines what’s possible when science meets circularity.

WHAT WE DO!

KUORI transforms tomorrow’s materials today—bridging innovation and sustainability without compromise. Our biodegradable BIOWA grades upcycle olive pits and nutshells into high-performance products, reducing microplastic pollution. With Material B, we are developing a 100% bio-based material that naturally returns to the earth, while our patent-pending vulcanized rubber, Material C, will regenerate through chemical recycling. No landfills, no legacy just smarter materials engineered to protect the planet while outperforming the status quo. Explore how KUORI redefines what’s possible when science meets circularity.

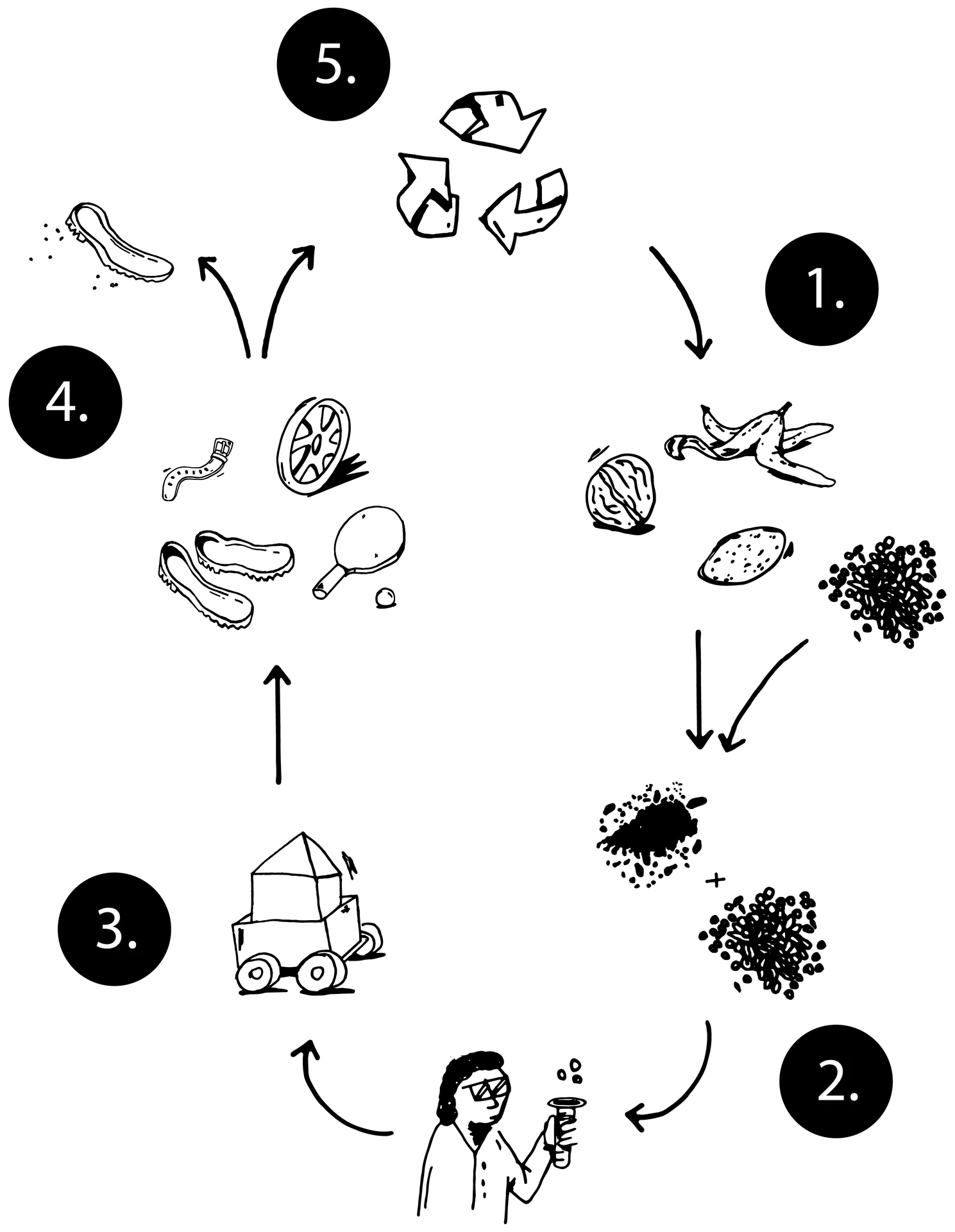

5. END OF LIFE - Products

At the end of its life, the product can be melted down and reshaped into new products, drastically reducing waste. By returning the material to its malleable state, we extend material's lifespan and contribute to a more sustainable manufacturing process.

KUORI is using 2nd generation bio-fillers such as walnut shells & olive pits, by-products of the food industry, blended with biopolymers and green additives to create sustainable materials.

1. SOURCE

4. END OF LIFE - Microplastics

Due to their chemical structure, microplastics released by the abrasion of the material will disappear by the action of water and enzymes activity.

2. RESEARCH

Our team of material scientists develops customized grades tailored to client specifications, collaborating with companies to optimize properties such as color, foaming and mechanical properties.

The resulting high-quality pellets are designed for traditional plastic manufacturing processes like extrusion, injection molding and 3D printing, offering an eco-friendly alternative to conventional plastics for shoe soles, outdoor and mobility applications.

3. APPLICATION

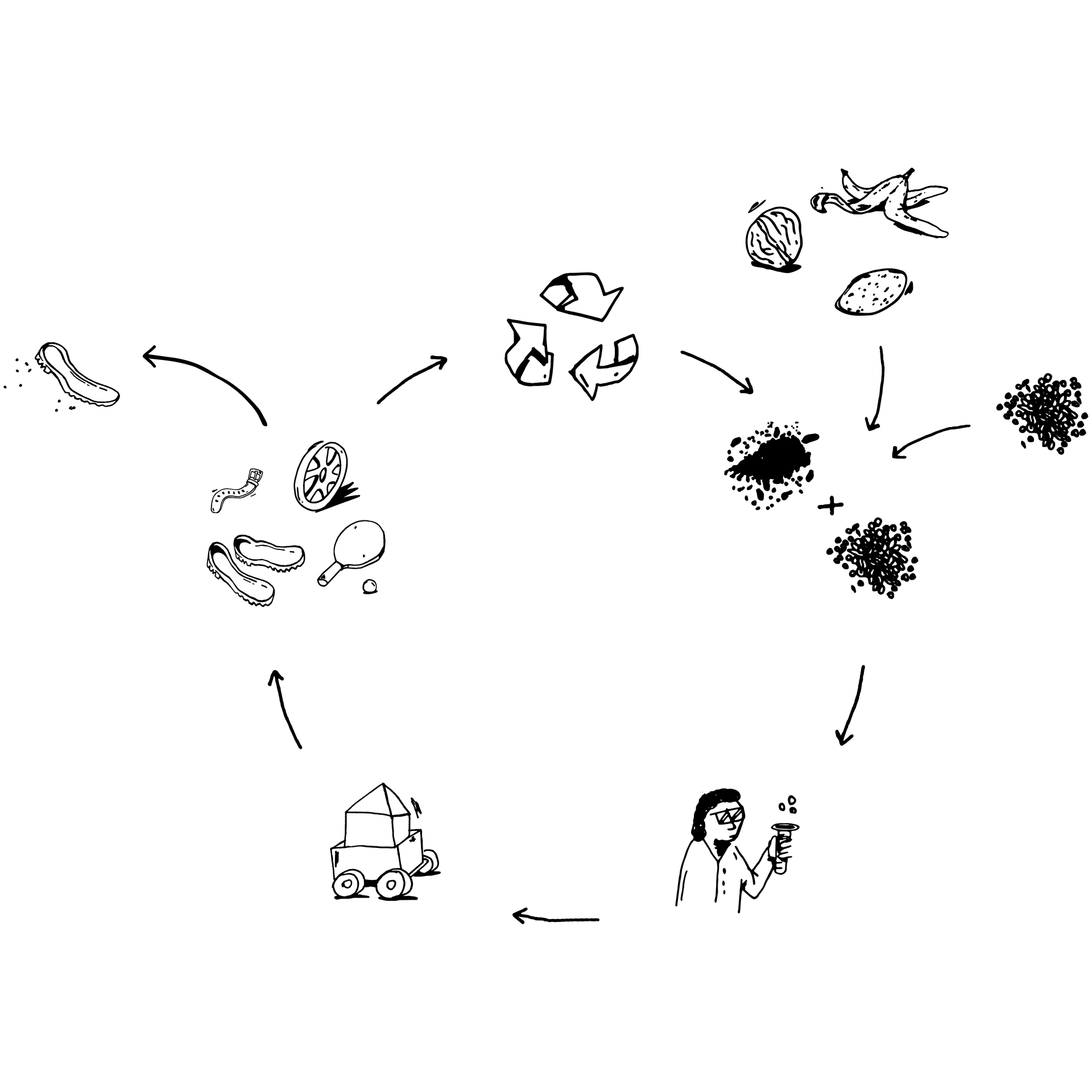

END OF LIFE - Products

At the end of its life, the product can be melted down and reshaped into new products, drastically reducing waste. By returning the material to its malleable state, we extend material's lifespan and contribute to a more sustainable manufacturing process.

SOURCE

KUORI is using 2nd generation bio-fillers such as walnut shells & olive pits, by-products of the food industry, blended with biopolymers and green additives to create sustainable materials.

END OF LIFE - Microplastics

Due to their chemical structure, microplastics released by the abrasion of the material will disappear by the action of water and enzymes activity.

RESEARCH

Our team of material scientists develops customized grades tailored to client specifications, collaborating with companies to optimize properties such as color, foaming and mechanical properties.

APPLICATION

The resulting high-quality pellets are designed for traditional plastic manufacturing processes like extrusion, injection molding and 3D printing, offering an eco-friendly alternative to conventional plastics for shoe soles, outdoor and mobility applications.

OUR MISSION

KUORI's mission is, to redefine the rubber and elastic materials industry towards a circular future without fossils, microplastic pollution, and excessive CO₂ emissions. Our eco-friendly alternatives are designed to perform just like conventional plastics while seamlessly fitting into existing manufacturing processes enabling efficient adoption and impactful change.

We address 5 of the 17 Sustainable Development Goals, focusing on creating a sustainable and prosperous future.

OUR MISSION

KUORI's mission is, to redefine the rubber and elastic materials industry towards a circular future without fossils, microplastic pollution, and excessive CO₂ emissions. Our eco-friendly alternatives are designed to perform just like conventional plastics while seamlessly fitting into existing manufacturing processes enabling efficient adoption and impactful change.

We address 5 of the 17 Sustainable Development Goals, focusing on creating a sustainable and prosperous future.

THIS IS KUORI

Our diverse team shares one unifying goal: shaping a greener, more sustainable future with KUORI

IN COLLABORATION

Together with trusted academic institutions, we’re pushing the boundaries of what’s possible.

In close collaboration with FHNW and the Institute of Polymer Engineering (IKT), we benefit from excellent research infrastructure and the expertise of Prof. Dr. Christian Rytka’s team to further develop and optimize our materials.

Our partnership with UZH focuses on environmental and economic modeling, leveraging LCA studies and cost calculations of our materials.

We regularly collaborate with HSG through student impact projects, Start Accelerator programs, and career events, gaining a dynamic platform to exchange ideas and foster innovation.

Together with EPFL, we are working on the analysis and optimization of our materials to understand and reduce their environmental impact.

Our collaboration with ZHAW leverages their extensive expertise to conduct in-depth biodegradation studies, supporting our efforts in circular materials innovation.

IN COLLABORATION

Together with trusted academic institutions, we’re pushing the boundaries of what’s possible.

JOIN US TO SHAPE THE FUTURE

Do you share our passion for sustainability and would like to create a positive impact on the planet? Join KUORI as we revolutionize materials to build a more sustainable future.

JOIN US TO SHAPE THE FUTURE

Do you share our passion for sustainability and would like to creating a positive impact on the planet? Join KUORI as we revolutionize materials to build a more sustainable future.

OUR STORY

Founded in 2022, KUORI's mission is clear: to break free from the world's dependence on oil-based plastics. Rather than accepting the conventional path, we asked ourselves a daring question: "What if we could drastically reduce microplastic pollution?" It is a significant question, but it is essential to push boundaries to drive real change.

Our journey began with an unconventional idea: upcycling food byproducts like olive pits, walnut shells, and banana peels into innovative, biobased, biodegradable elastic materials. Imagine a material that is not only environmentally friendly but also rivals the utility of conventional plastics, all while seamlessly integrating into existing manufacturing systems.

At our Swiss headquarters and research center, we merge Swiss quality with creative innovation. Our philosophy is simple yet transformative: circularity by design and eco-effectiveness. Every material we develop is biobased and biodegradable because settling for less isn't an option when the stakes are this high.

This unique positioning has set us on a path to becoming a multi-million company in the coming years, proving that the market is ready for sustainable innovation.